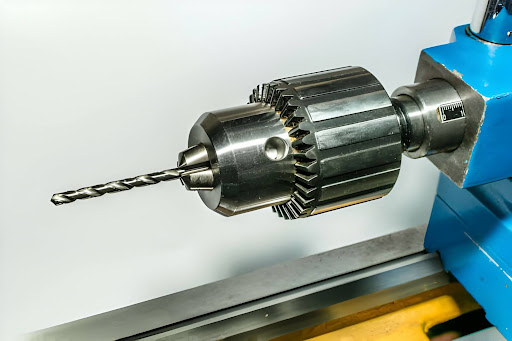

Jacobs drill chucks are an essential part of many power tools, including drills and drill presses. They securely hold the drill bits in place and allow for efficient drilling operations.

However, like any tool, Jacobs drill chucks require regular maintenance and occasional repairs to ensure they function properly. In this article, we will discuss some tips for maintaining and repairing Jacobs drill chucks to keep them in top working condition.

Regular Cleaning

One of the most important maintenance tasks for Jacobs drill chucks is regular cleaning. Over time, dust, debris, and metal shavings can accumulate inside the chuck, causing it to become stiff or difficult to operate.

To clean the chuck, start by removing the drill bit and wiping down the inside with a clean cloth. You can also use a small brush to remove any stubborn debris. Be sure to also clean the outside of the chuck to prevent any buildup that could affect its performance.

Regularly cleaning Jacobs drill chucks is crucial for maintaining their performance and functionality. Dust, debris, and metal shavings can build up over time, leading to stiffness or difficulty in operation. To clean the chuck, begin by removing the drill bit and wiping the interior with a clean cloth.

Lubrication

Another key maintenance tip for Jacobs drill chucks is proper lubrication. Applying a small amount of lubricating oil to the chuck’s moving parts can help reduce friction and ensure smooth operation. Be sure to use a lubricant that is compatible with the chuck’s materials to avoid any damage.

It’s recommended to lubricate the chuck after cleaning it to keep it in good working condition. Regular lubrication is essential for maintaining Jacobs drill chucks. By applying a small amount of lubricating oil to the moving parts, you can prevent excessive friction and ensure that the chuck operates smoothly.

It is important to use a lubricant that is suitable for the materials used in the chuck to prevent any potential damage. It is advisable to lubricate the chuck after cleaning it to prolong its lifespan and keep it working efficiently.

Checking for Wear and Tear

Regularly inspecting the Jacobs drill chuck for any signs of wear and tear is essential for preventing larger issues down the line. Look for any cracks, chips, or other damage to the chuck body or jaws.

If you notice any damage, it’s important to address it promptly to prevent further deterioration. In some cases, replacing the damaged parts may be necessary to ensure the chuck functions properly.

Proper Storage

Proper storage of Jacobs drill chucks can also help prolong their lifespan. When not in use, store the drill with the chuck facing downward to prevent dust and debris from settling inside.

Additionally, consider using a protective cover or case to shield the chuck from any potential damage. Storing the tool in a clean, dry environment can also help prevent rust and corrosion, which can affect the chuck’s performance. Proper storage of Jacobs drill chucks can help prolong their lifespan.

When not in use, it is advisable to store the drill with the chuck facing downward to prevent dust and debris from settling inside. It is also recommended to use a protective cover or case to shield the chuck from any potential damage. Storing the tool in a clean, dry environment can further prevent rust and corrosion, which can negatively impact the chuck’s performance over time.

Calibration

Calibrating the Jacobs drill chuck is another important aspect of maintenance. If you notice that the chuck is not holding the drill bit securely or is slipping during use, it may need to be recalibrated. Follow the manufacturer’s instructions for adjusting the chuck’s tightness to ensure it grips the drill bit properly.

Proper calibration can help prevent accidents and ensure accurate drilling. Calibrating the Jacobs drill chuck is crucial for maintaining its functionality. If you observe that the chuck is not securely holding the drill bit or if it slips during operation, it is essential to recalibrate it.

Refer to the manufacturer’s guidelines for adjusting the chuck’s tightness to guarantee that it effectively grips the drill bit. Accurate calibration not only helps in preventing accidents but also ensures precise and efficient drilling operations.

Repairing Jaws

If the jaws of the Jacobs drill chuck become worn or damaged, they may need to be repaired or replaced. To repair the jaws, you can use a file to smooth out any rough edges or burrs.

If the damage is more severe, you may need to purchase replacement jaws from the manufacturer. Be sure to follow the manufacturer’s instructions for replacing the jaws to ensure proper installation.

Seeking Professional Help

If you encounter any issues with your Jacobs drill chuck that you are unable to resolve on your own, it’s best to seek help from a professional. A qualified technician will have the expertise and tools needed to diagnose and repair any issues with the chuck. Attempting to repair complex problems without the necessary skills can lead to further damage and may compromise the safety of the tool.

Conclusion

Maintaining and repairing Jacobs drill chucks is essential for ensuring their longevity and performance. By following the tips outlined in this article, you can keep your drill chucks in top working condition and prevent costly repairs or replacements.

Remember to regularly clean and lubricate the chuck, check for wear and tear, store it properly, calibrate as needed, and seek professional help when necessary. With proper care, your Jacobs drill chucks can continue to serve you well for years to come.